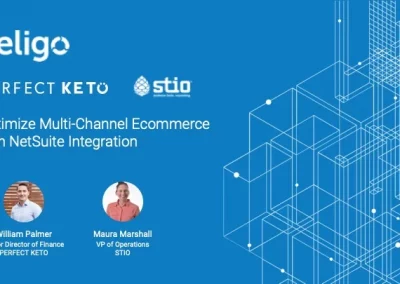

On Demand Webinar

How Businesses Can Leverage 3PL Integration for Operational Efficiency

About The Speaker

Brandon Burns

Director of Business Development

3PL Central

Brynn Roberts

NetSuite Administrator

Specialty Incentives

Chris Bidleman

Director, Integration Solutions

Celigo

Chris Bidleman is the Director of Solutions Integrations and heads up the Solution Architect team at Celigo. Chris has been with Celigo for over 9 years in a variety of roles including project management and services engineering manager. Prior to Celigo Chris worked with a variety of consulting and software companies focused on solution driven results in healthcare IT and supply chain management with a focus on eProcurement and ecommerce for over 20 years.

Meet Celigo

Celigo automates your quote-to-cash process with an easy & reusable integration platform-as-a-service (iPaaS), trusted by thousands of eCommerce and SaaS companies worldwide.

Use it now and later to expedite integration work without adding more data silos, specialized technical skillsets or one-off projects.

Related Resources